This article reviews different types of flame detectors used in the main burners of boilers and discusses their role in improving performance and enhancing the overall safety level of the Burner Management System (BMS) in steam units. The operating principles of these detectors are also described.

Introduction

The Burner Management System (BMS) is designed and installed to ensure safe operation of boilers during startup, shutdown, and load increase or decrease. This system consists of key components such as main burner flame detectors, igniter flame detectors, Programmable Logic Controller (PLC), and actuators for fuel, steam valves, and air dampers. Improving the performance and safety of each of these elements directly leads to better overall operation and enhanced safety of the entire BMS.

The main cause of furnace explosions is the ignition of an explosive fuel-air mixture accumulated inside the furnace or in exhaust gas ducts. The severity of such explosions depends on the ratio of fuel to air present at the time of ignition. Furnace explosions can occur due to operator errors, improper system design, or malfunction of BMS components such as flame detectors, logical analyzers, or valve and damper actuators.

The NFPA 8502 standard discusses design, installation, and logic requirements of BMS to prevent accidents.

The IEC 61508 standard specifies hardware and software design requirements for BMS to qualify as a Safety Instrumented System (SIS).

In addition, FM 7610 and EN 298 standards define safety requirements for flame detectors. It is important to note that a SIS is a type of process control system that performs specific safety functions in industrial processes. Therefore, to ensure the BMS qualifies as a SIS, the design and manufacturing of its components such as flame detectors, logic analyzers, valves, and dampers must comply with these standards. This paper focuses on the flame detector system and provides an overview of relevant standards.

Burner Management System (BMS)

The main functions of the BMS can be summarized as follows:

- Establishing system interlocks and preventing startup when defined conditions are not met;

- Rapidly shutting off fuel supply automatically when required;

- Controlling the ignition system and verifying the formation of the igniter flame;

- Monitoring the main burner flame and ensuring ignition, or otherwise closing fuel valves and opening the exhaust gas vent;

- Supervising furnace purging operations;

- Monitoring for possible fuel leaks.

-

Flame Detector

In a BMS, one of the most critical elements is the flame detector, which plays a vital role in furnace protection and explosion prevention. The flame detection system has two key functions:

- Notify the operator of unstable combustion so that corrective actions can be taken;

- Automatically shut down the burner in hazardous conditions where unburned fuel may accumulate.

-

Types of Flame Detectors

There are three general types of flame detectors:

- Ionization (Rod) Flame Detector, used mainly in igniter burners;

- Radiation Flame Detectors, which are the main subject of this paper;

- Optical or Visual Flame Detectors, which use CCTV cameras to capture video signals that are processed to detect the presence of a flame. The analyzer interprets these signals and activates the output when a flame is detected.

-

Radiative Properties of Flame

The radiative emission of a flame is essential for flame detection systems, especially in multi-burner boilers.

The electronic circuits of a flame detector operate based on these radiative characteristics, which provide appropriate input signals to reduce the flame failure response time (FFRT) typically between one and five seconds, depending on fuel type and signal intensity. Flames emit a wide range of electromagnetic waves known as the flame spectrum, which includes ultraviolet (UV), visible, and infrared (IR) radiation. The UV and IR regions are at opposite ends of the spectrum, while only 400-800 nm is visible to the human eye. Blue light lies near the UV region, and red light near the IR region. Flame detectors are sensitive to UV, visible, and IR radiation, and several parameters affect the selection of the proper type of detector.

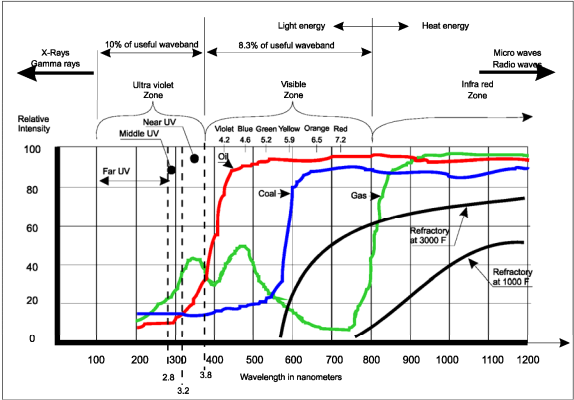

Figure (1) shows the flame spectrum for different fuels, which serves as the basis for selecting the suitable flame detector for each burner type.

Figure (1)

The ultraviolet (UV) radiation constitutes the lowest portion of the total radiation emitted by a flame among the three spectral regions – UV, visible, and infrared (IR). Typically, the first one-third of the flame length is the primary source of UV radiation. High-temperature flames generate significant amounts of UV radiation, while gas and liquid fuel flames emit sufficient UV intensity to be reliably detected by flame detectors. The visible light radiation represents approximately 10% of the total emission, appearing to the human eye as various colors depending on the combustion characteristics.

-

UV Flame Detection

UV flame detectors employ ultraviolet sensors that are sensitive to wavelengths between 190-400 nm.

The circuit design includes a signal discrimination stage to distinguish the main flame from nearby flames or background radiation emitted by hot furnace walls. This circuit minimizes interference by filtering out unwanted background signals such as those from hot refractory walls or igniters. UV flame detectors are particularly effective for gas and oil flames, which emit sufficient UV radiation for reliable detection.

-

Visible and Infrared Flame Detection

Visible and IR flame detectors use a combination of lenses, sensors, and frequency-adjustment circuits.

Infrared radiation, together with visible light, constitutes about 99% of the flame’s radiative energy. However, since hot furnace surfaces also emit visible and infrared radiation, measuring light intensity alone is not a reliable indicator of flame presence.

The radiation from furnace walls is steady, while the flame itself produces fluctuations at a specific frequency (flame flicker), caused by rapid micro-explosions of fuel and oxygen at the molecular level. By analyzing the intensity and flicker frequency typically between 5-200 Hz, depending on burner type and fuel the system can distinguish between flame signals and background radiation.

Liquid and coal-fueled flames emit strong visible and IR radiation, while gas flames emit weaker signals in these bands. Using band-pass or high-pass frequency filters allows the detector to ignore adjacent flames and background interference, ensuring accurate flame detection.

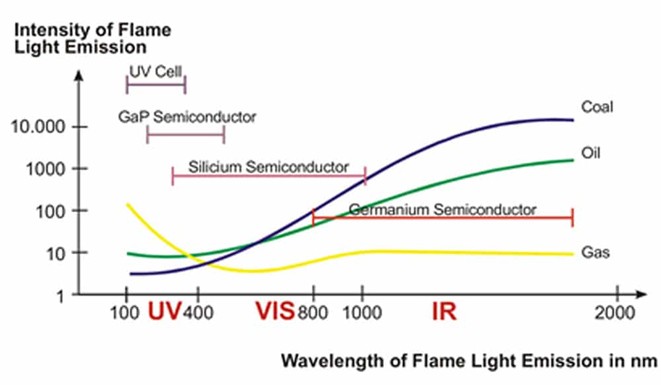

Figure (2) illustrates the radiation spectra of various fuels and the corresponding flame detector types suitable for each.

Figure (2)

Conclusion

Flame detectors are among the most critical safety instruments in a boiler system. They prevent unsafe conditions and improve overall combustion reliability by promptly detecting flame loss and distinguishing it from background radiation. Proper application and precise selection of flame detectors based on fuel type and burner design not only increase the system’s emergency response speed but also enhance the overall boiler efficiency and reduce maintenance costs.

- Author: Engineer Hamid Katebi.

- Author’s LinkedIn profile

For further information, please contact Noor Parto Co.