In most industrial systems, heat is generated through the combustion of fuels such as gas, oil, or solid hydrocarbons. Boilers and furnaces are among the key sources of thermal energy that provide the necessary heat for various industrial processes and energy generation. In boilers, the produced heat is used to convert water into steam, which in turn drives turbines and supplies the required thermal energy for process operations in refineries, petrochemical plants, and other industries.

Because combustion is a highly sensitive and potentially hazardous process, the safety and reliability of the flame are of utmost importance. Any disturbance in the combustion process such as fuel leakage or improper air-fuel mixture may lead to incomplete burning, flameout, or even explosion. Therefore, continuous monitoring of the flame is an essential safety requirement in all combustion systems.

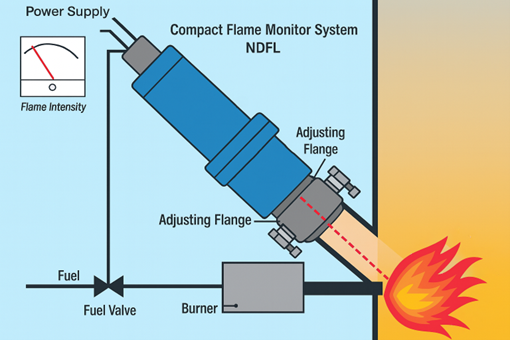

To ensure safe operation, modern control systems are equipped with flame monitoring and detection devices, which continuously confirm the presence of a stable flame and initiate an automatic shutdown of the fuel supply if the flame disappears unexpectedly. This automatic reaction time is known as Flame Failure Response Time (FFRT) the period during which the system must detect flame loss and interrupt the fuel flow to prevent unsafe conditions.

Types of Industrial Boilers and Furnaces

Industrial boilers and furnaces are designed in various forms depending on their function and application. Boilers are typically closed pressure vessels where fuel and air are mixed and ignited inside a combustion chamber to generate heat. The produced heat is transferred through heat-exchange surfaces such as economizers and superheaters to convert water into saturated or superheated steam. This steam may then be used for electricity generation in thermal power plants or as process steam in petrochemical and metallurgical industries.

In contrast, process furnaces are used for direct heating of materials such as in refining crude oil, heat treatment of metals (annealing, hardening), or chemical and ceramic processes. Furnaces are usually designed for high-temperature operations and continuous heat transfer to the process medium inside the chamber.

Difference Between Boilers and Furnaces

While both systems involve controlled combustion and heat transfer, the boiler operates under pressure and produces steam, whereas the furnace directly heats materials or process streams. In boilers, the combustion chamber, burners, and ignition systems are part of a pressure vessel, making safety and monitoring more complex. Furnaces, on the other hand, may operate at lower pressure but much higher surface temperatures.

Both use burners, fuel delivery systems, and ignition controls, yet the operational environment such as temperature, vibration, and gas composition can vary significantly. For this reason, proper flame detection and control systems are vital to prevent unburned fuel accumulation, backfire, or explosion during ignition and shutdown sequences.

Importance of Flame Detection in Combustion Safety

A stable flame ensures that fuel is being burned completely and safely. If combustion is interrupted due to a failure in the burner, fan, or fuel line, unburned fuel may accumulate inside the furnace. When mixed with air, this can lead to a dangerous explosion upon re-ignition. Therefore, flame monitoring systems often referred to as flame detectors or flame scanners are critical safety components in both boilers and furnaces.

In industrial systems, the flame detector acts as the “eye” of the furnace, confirming whether the flame exists. These devices use optical sensors that detect specific wavelengths of radiation emitted by the flame. Depending on the fuel type and combustion characteristics, the detectors may use ultraviolet (UV) or infrared (IR) sensors or a combination of both (UV/IR)

Once installed, the flame detector continuously monitors the flame and sends electrical signals to the burner management system (BMS). If the flame signal disappears, the BMS immediately cuts the fuel supply and shuts down the burner to prevent unsafe conditions.

Classification of Flame Detectors Based on Installation

Flame detectors can be classified according to their installation position and application environment in the burner system:

-

Flame Detectors for Boilers

Boiler flame detectors are typically installed directly on the sealed and pressurized combustion chamber. They must withstand high temperatures and detect the flame through the optical window of the burner. These detectors are often used with gas, oil, or dual-fuel burners, and their sensors are selected based on the dominant radiation characteristics of the flame (for example, UV sensors for natural gas and IR sensors for heavy oil or coal flames).

-

Flame Detectors for Process Furnaces

In large industrial furnaces, especially in refineries and petrochemical plants, the flame may not always be directly visible. These furnaces often have multiple burners distributed around the chamber. The flame detectors are positioned to monitor each burner individually or through optical ports that provide a clear line of sight to the flame. Due to high wall temperatures and strong background radiation, these systems require special optical filters and temperature-resistant designs to distinguish the flame radiation from the surrounding hot surfaces.

Installing NoorParto’s flame detector on the boiler of the Bidblond refinery

Direct and Indirect (Fiber Optic) Flame Detection

Flame detectors are categorized into direct line-of-sight and indirect (fiber optic) types:

- Direct flame detectors are mounted directly on the furnace or boiler, viewing the flame through an optical lens or sighting tube.

- Indirect or fiber optic detectors are used when direct installation is not possible due to excessive heat, limited space, or vibration such as in gas turbines. In this case, a flexible optical fiber transmits the flame light from the combustion chamber to the detector, which can be installed farther away in a cooler area.

Both types operate based on the same principle: the flame’s light energy is focused on a photodetector, which converts it into an electrical signal. The system processor analyzes the signal frequency and intensity to confirm the flame’s presence or absence.

How the flame works in direct view

Key Factors in Selecting Flame Detectors

When selecting a flame detector for an industrial furnace or boiler, engineers must consider several critical factors:

-

Type of Fuel and Combustion Process

The fuel type (natural gas, oil, diesel, coal, etc.) determines the spectral emission characteristics of the flame.

- Hydrocarbon flames typically emit in both UV (200–400 nm) and IR (800–2500 nm) ranges.

- For highly luminous flames (e.g., oil, coal), IR sensors are often more effective, while for clean gas flames, UV sensors provide faster and more reliable detection.

-

Installation Conditions

Environmental factors such as temperature, vibration, dust, moisture, and corrosive gases can affect sensor performance and lifetime. Detectors must be installed in a way that avoids direct exposure to excessive heat or soot. For high-temperature areas, fiber optic models are preferred, allowing the main electronics to remain in a safe location.

Fiber optic system used in indirect flame detectors

-

Explosion Protection and Safety

In hazardous areas where flammable gases are present, the detector must be explosion-proof (ATEX / Ex certified) to prevent ignition. Noor Parto has developed a range of explosion-proof flame detectors to meet these stringent industrial requirements.

-

Distance and Viewing Angle

The detector’s field of view (FOV) and optical sensitivity must be compatible with the geometry of the combustion chamber and burner arrangement. Obstructions or reflections should be avoided by proper alignment and selection of viewing ports.

-

False Signal Prevention

Detectors must be resistant to false alarms caused by reflections from hot surfaces, glowing metal parts, or electrical interference. Proper shielding, grounding, and maintenance of the optical window help ensure accurate and stable performance.

Maintenance and Calibration

Regular inspection and cleaning of the optical lens or window are necessary to prevent soot or dust buildup, which can reduce sensitivity. Periodic calibration and testing by qualified technicians ensure reliable operation and compliance with safety standards. Many modern flame detectors, including Noor Parto models, feature self-check functions that automatically monitor sensor health and report any failure to the control system.

Conclusion

Continuous flame monitoring is an essential part of every combustion system. In boilers and furnaces, any failure to detect the flame promptly can lead to serious safety hazards and production losses. By using reliable and well-calibrated flame detectors, industries can achieve higher safety, efficiency, and compliance with international standards.

The advanced flame detection technologies developed by Noor Parto Co. including UV, IR, and UV/IR models with explosion-proof options have significantly improved combustion safety in Iranian industries and reduced dependence on imported systems.

For further information, please contact Noor Parto Co.